With the data we collect by placing our sensors inside the blades of wind turbines, we enable maintenance and repair activities before the damage to the blades reach the surface.

We extend the life of wind turbines by producing meaningful results with the data we keep in the cloud and our algorithm.

With the data we collect by placing our sensors inside the blades of wind turbines, we enable maintenance and repair activities before the damage to the blades reach the surface.

We extend the life of wind turbines by producing meaningful results with the data we keep in the cloud and our algorithm.

Our software can classify different types of damage such as cracks, fractures, burns on the blades of wind turbines and gives information about the location and damage size.

The platform uses a machine learning algorithm and a neural network approach to process data collected from vibration sensors and detect damage to wind turbine blades at an early stage.

Communication with station via LoRaWANK, or alternatively Wi-Fi. Non-invasive installation with adhesives or vacuum options. Collects data from MEMS sensors placed in the blade of the wind turbine.

Small fractures can be costly if they grow. Detect blade damages before they reach the surface and become costly to repair

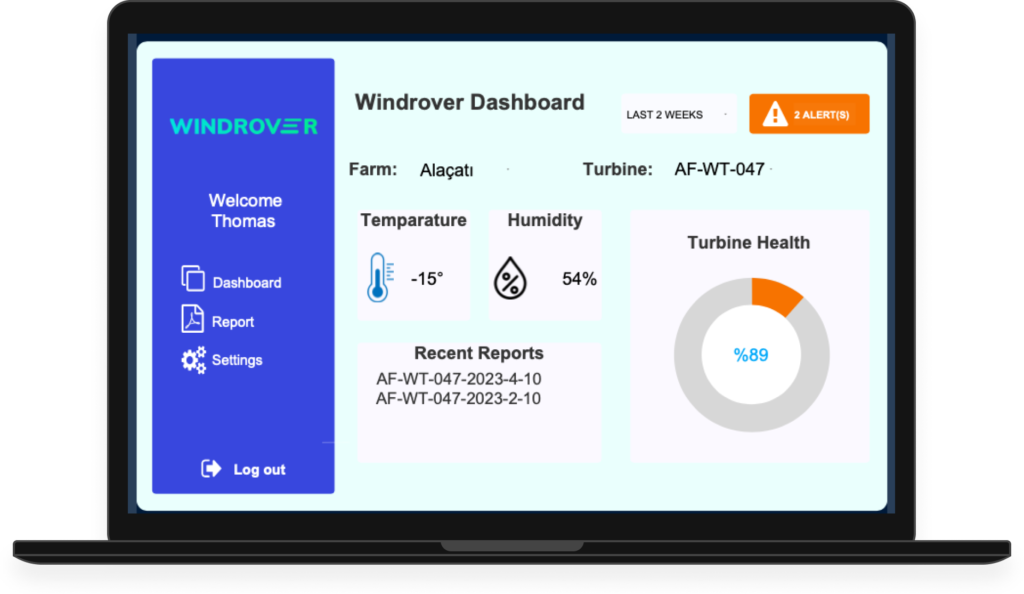

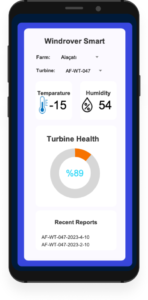

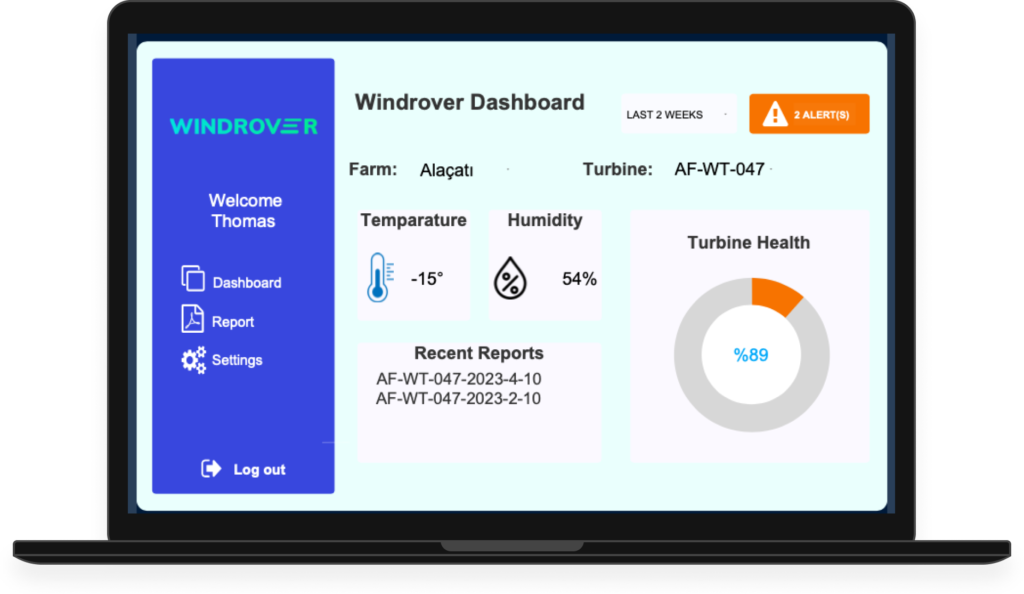

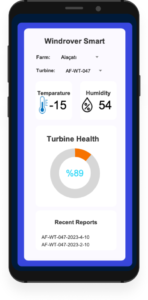

Cloud platform displays the real time data collected from wind-turbines enabling continuous wind turbine blade condition monitoring and off-site reporting

Predictive analysis and continuous monitoring to decrease the turbine downtime and lengthen the lifetime of the blades.

System will notify the corresponding divisions and stakeholders on detected irregularities that could possibly lead to blade damage.

Small fractures can be costly if they grow. Detect blade damages before they reach the surface and become costly to repair

Cloud platform displays the real time data collected from wind-turbines enabling continuous wind turbine blade condition monitoring and off-site reporting

Predictive analysis and continuous monitoring to decrease the turbine downtime and lengthen the lifetime of the blades.

System will notify the corresponding divisions and stakeholders on detected irregularities that could possibly lead to blade damage.

Interested? Download our product catalogue

for full-features

Check this mostly asked questions from real clients.

Windrover AI can detect and predict any kind of damages( cracks,splits, holes) on the blades.

Windrover AI is suitable for all environmental conditions.

Since Windrover AI knows wind turbine blades’ vibration signature, noises in and around the data can easily separate.

Drone inspections can only measure damages on the surface, however Windrover AI provides detection of early stage damages and prediction of latter damages.

Data is automatically uploaded to the cloud and is available 24/7 on the dashboard once you log in.

Windrover indicates which blade has damage.From this continuously updated information, you can then decide which turbine needs attention. Once data is collected enough, Windrover will be able to label damages and measure their sizes.

When Windrover is installed for the first time, a baseline period of four weeks commences. During this period results from turbines with blades of the same design are compared. Additionally, onboard metrics can identify particular characteristics associated with blade damage. These then work together to determine the level of pre-existing damage, regardless of the age of the blades at the time of first install.

Contact us if you are curious about this revolutionary solution that puts the wind industry a decade forward, making wind farms work like a spaceship!